KTR says that the technology could open up new Atex applications – such as compact designs with necked-in hubs – as well as being used to produce customised shaft-cam links.

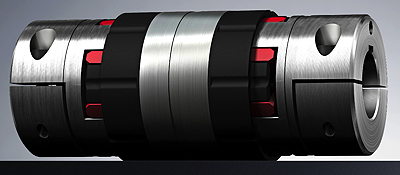

The new coupling is Atex-certified and is claimed to offer good dynamic properties and a low moment of inertia. It dampens torsional vibration during power transmission and absorbs shocks resulting from unbalanced machinery. It is available in single or double cardan designs that can accommodate large shaft misalignments.

KTR’s non-sparking coupling is available in single or double cardan versions

Torque will continue to be transmitted, without any risk of sparking, even of the spider element becomes worn, allowing maintenance to be delayed to a convenient time.