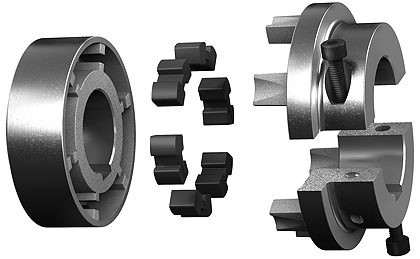

The short-shaft coupling, which conforms with DIN 740, is made of grey cast-iron. The input and output shafts can be pushed together by 3–6mm, depending on the size. The torque is transmitted via elastomer packages which also compensate for misalignments and dampen shocks and torsional vibrations. Should the elastomers fail due to extreme loads, the fail-safe coupling continues to hold the torque.

In the type N version of the coupling, both the pocket and the cam part consist of standard hubs.

In the SH Split design, the cam hub is separated into two halves by “fracture cutting”, or “cracking”. The resulting fracture surfaces centre the halves precisely with each other, making incorrect assembly almost impossible. Depending on accessibility, the hub can be pushed on for assembly. Or the two hub halves can be joined around the shaft. The split hub can therefore be radially installed and removed without dismantling the adjacent units.

“We recommend that our customers fit the split hub onto the motor shaft,” says KTR product manager, Michael Brüning. “This makes the coupling easier to assemble overall and, in case of service, there is more space available – for example, to exchange the elastomer packs. In addition, it allows the user to carry out the direction of rotation check on the engine without the coupling hub."

In KTR’s Roflex SH Split coupling, the cam hub is split into two halves

The coupling can be used in potentially explosive atmospheres and complies with the Atex directive (2014/34/EU).