“We are able to record the torque used to tighten hundreds of thousands of bolts, for example, and store that information in a database,” Slama explains. “The information makes it possible to quickly identify any discrepancies, and it provides users with clues as to the possible causes of faults.”

The connected tools could also help in troubleshooting. If a worker tries to use a tool for the wrong task or at the wrong place, the tool could power itself down, preventing errors from occurring and helping to improve safety, quality, and productivity.

The IIC testbed highlights key aspects of digitally-connected manufacturing. One example is cross-industry cooperation among companies who are working to create open standards to exchange data.

Tests on the Track & Trace components are underway at Bosch Software Innovations in Berlin, and at Tech Mahindra in Bangalore, India, to determine how they interact with each other. The first pilot applications at industrial user sites are planned for later this year.

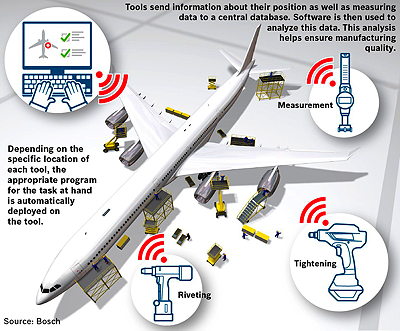

The Industrial Internet Consortium's Track & Trace testbed project will help to manage shopfloor tools, especially in complex production environments such as aircraft assemby

In the future, open standards will allow power tools – used for duties such as drilling, tightening, measuring and soldering – to be integrated into networks.