The system uses a smart gateway, based on the OPC UA open communications standard, that allows manufacturer-independent integration with most modern control systems. It increases availability and cuts operating costs by reducing planned and unplanned downtime through predictive maintenance.

Remote access to machine data opens up new opportunities for preventative and demand-based maintenance and provides the basis for data analysis and new business models. The system can collect data such as current and voltage as well as providing performance data, energy consumption figures, and diagnostic and maintenance information. The modules can be integrated with the Automation Studio software from ABB’s B&R subsidiary and, via OPC UA, with any PLC or higher-level system.

“Novolink modules address the key challenges of the industry: digitalisation and energy efficiency,” explains ABB’s head of mechanical engineering segment support, Sven Glöckler. “This solution, which is particularly suitable for retrofits and modernisations, creates a bridge from conventional switching technology to the world of Industry 4.0 via an OPC UA interface.

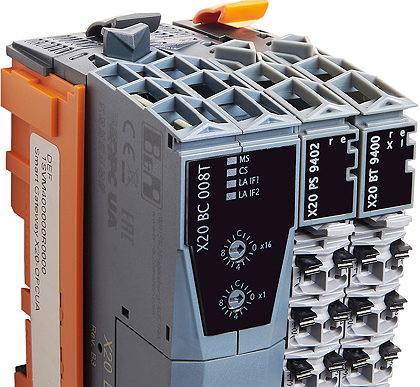

The Novolink system gateway offers open communications via OPC-UA with PLCs and other systems

“This allows seamless integration into system solutions from all third-party providers,” he continues. “The comprehensive data availability offers users the opportunity to implement new maintenance concepts, increase their operational efficiency and, at the same time, optimise energy consumption.”

ABB: Twitter LinkedIn Facebook