By combining Mitsubishi’s control technology and manufacturing expertise with Visual Components’ capabilities, the JV will strengthen Mitsubishi’s Melsoft Gemini 3D simulator, which can help to overcome labour shortages, raise productivity, and improve manufacturing quality.

The JV’s Finnish development base will allow it to take advantage of Visual Components' expertise in verifying device control using 3D simulators, improving design efficiencies by generating control logic, and enhancing productivity using manufacturing data. Visual Components was a pioneer in the 3D manufacturing simulation, and has more than 20 years of experience in the field. It has 123 employees.

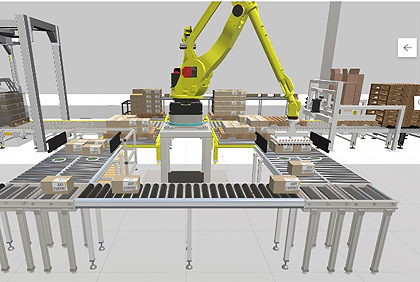

The company’s software is compatible with Mitsubishi’s factory automation products and uses standard functions to connect with PLCs and robots, as well as interfaces for expanding the functions of 3D simulators.

“For companies aiming to optimise the entire product lifecycle, 3D simulation is essential,” suggests Visual Components’ CEO, Mikko Urho. “This joint venture allows us to maximise synergy by combining Visual Components’ 3D simulation software with Mitsubishi Electric’s manufacturing expertise. Through this synergy, we will accelerate the realisation of digital manufacturing and contribute to enhancing our customers' competitiveness.”

Mitsubishi’s Melsoft Gemini 3D simulator, released last year, is a digital twin platform that uses 3D technology to create virtual production lines and facilities in digital spaces, allowing users to cut design, equipment and line set-up workloads, as well as reducing TCO (total cost of ownership) in their engineering chains. Gemini links cyber-physical systems, enabling businesses to visualise, simulate and streamline operations from design to maintenance.

Visual Components specialses in 3D simulations for manufacturing

Mitsubishi and Visual say that the joint venture positions them at the forefront of digital transformation, offering tools to help manufacturers in their automation efforts, from product planning to commercialisation.

“Specifically, we aggregate and analyse data acquired from equipment and equipment at manufacturing sites using our FA equipment in a digital space to solve problems in our customers’ engineering chains,” explains Toshie Takeuchi, general manager of Mitsubishi’s FA System Division. “By establishing a joint venture with Visual Components, we will combine the strengths of both companies and contribute to solving problems at manufacturing sites.”

“3D digital simulation tools like Melsoft Gemini play a pivotal role in evaluating intricate production systems, allowing manufacturers to circumvent costly errors, expedite decisions, and enhance product quality,” Urho adds. “We are excited about the future and the immense potential this collaboration holds.”

Mitsubishi Electric: LinkedIn Facebook

Visual Components: x LinkedIn Facebook