ABB claims that Visual Slam offers significant advantages over other types of navigation, such as magnetic tape, QR codes and 2D Slam systems, that need additional infrastructures to function.

ABB Robotics president Marc Segura predicts that the technology will make operations “faster, more efficient and more flexible, while freeing up employees to take on more rewarding work”.

AMRs equipped with the technology can operate safely in dynamic, human-populated environments, offering more autonomy and intelligence, he adds. Visual Slam “provides a new level of intelligence for AMRs that transforms robotic applications, from production and distribution through to healthcare.”

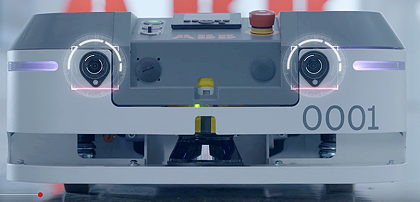

The technology uses cameras on the AMR to create a real-time 3D map of surrounding objects. It can differentiate between fixed references – such as floors, ceilings and walls, that need to be added to the map – and moving objects such as people or vehicles. The cameras detect and track features in the environment, allowing the AMR to adapt to its surroundings and to determine the safest, most efficient route to its destination. Unlike 2D Slam, the 3D version does not need additional references such as reflectors or markers, thus cutting costs, saving space and achieving positioning to within 3mm.

The Visual Slam technology will make AMRs more flexible and efficient, while cutting commissioning times by up to 20%

ABB says that by eliminating the need to change the environment, stop production or add infrastructure, the new technology can cut commissioning times by up to 20% compared to 2D Slam systems, making it quicker to add new AMRs into existing fleets. The technology is secure, because it analyses raw data only, with no visual images being saved on either the robot or on a server.

ABB has developed the Visual Slam AMRs in collaboration the Swiss AI and 3D specialist Sevensense Robotics, with which it formed a partnership in 2021. The technology will be available on ABB’s T702V AMRs from Q3 2023 and its P604V AMRs from Q4 2023. These will be followed by other AMRs.

ABB Robotics: Twitter LinkedIn Facebook