The researchers – from the Chalmers University of Technology in Gothenburg – were looking for ways to reduce the size, weight and costs of on-board chargers. Because the motor and inverter are not usually used during the battery-charging process, they examined the possibility of incorporating them into the charger circuit.

“Instead of having a separate isolated battery charger, we introduced a new concept for power transfer – the rotating transformer – which was developed to transfer electric power while rotating,” says Saeid Haghbin, who worked on the new system as part of a doctoral thesis in power engineering. “The battery is charged through the transformer, and a split-phase electric motor that was designed especially for this purpose.”

The integrated drive-charger is still at the laboratory stage and further development will be needed to achieve a practical version. However, the concept has secured Swedish and international patents. The university is trying to find a potential industrial user, and Volvo is also working on the technology.

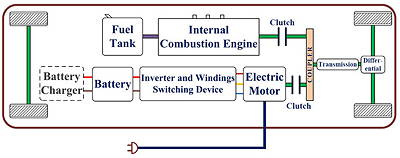

The key elements of the integrated drive and charging system in a plug-in hybrid vehicle configuration. Pure electric versions are also possible.

“Electric cars have been discussed as a possible solution to reduce carbon emissions for a long time, but scientists debate whether this mode of transportation is the future or not,” says Haghbin. “If we manage to solve the main problems with the battery and the battery chargers, I think the electric vehicles will succeed. And in general, I think electric transportation will become more common in the future – for example, trains, trams and plug-in hybrids.”