Related articles:

Space-saving pneumatic valves `set new standards`

Published: 17 May, 2010

![]() Festo has launched a new generation of pneumatic valves which, it claims, offer “a size-to-performance ratio never before achieved by any other valve”. The VUVG valves are based on a patented cartridge design which achieves extremely high power densities and will allow smaller valves to be used than at present in around 90% of all applications. Alternatively, the valves will operate more dynamically with faster cycle times than conventional valves of a similar size, achieving flow rates up to 100% higher.

Festo has launched a new generation of pneumatic valves which, it claims, offer “a size-to-performance ratio never before achieved by any other valve”. The VUVG valves are based on a patented cartridge design which achieves extremely high power densities and will allow smaller valves to be used than at present in around 90% of all applications. Alternatively, the valves will operate more dynamically with faster cycle times than conventional valves of a similar size, achieving flow rates up to 100% higher.

According to Festo, these are the valves “that the automation market has been waiting for”.

The new cartridge design incorporates a unique seal profile that allows vacuum operation, high flow rates and a pressure range of up to 10 bar. The high pressure and the use of smaller cylinders lead to shorter cycle times and more dynamic performance. As a result, when the valves are used, for example, with a 25mm piston diameter cylinder with a 160mm stroke and 350mm tube length, the advancing time at 10 bar is 88% faster than with conventional valves.

The cartridge design also supports separated two-pressure operation. There is no overlapping between the air ducts as is common with other valves.

The valves are said to be particularly suitable for use in applications needing cost-effective, compact devices with high flow rates. Their small size, combined with the low weight of their aluminium housings, also makes the valves ideal for uses such as direct mounting on robot arms.

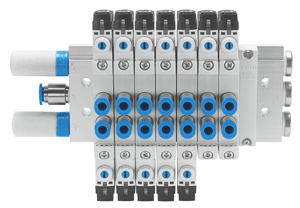

Two 3/2-way valves can be combined in one housing that can operate two single-acting cylinders, thus halving the required installation space.

There is no need for adapters or mounting attachments when installing the valves. Axial mounting bores allow individual valves to be assembled in series without special manifold strips or brackets, creating a valve manifold from a single valve. Multiple pressure zones can be set up easily using separating plates. Integrated LEDs provide a 360° view of the valve status.

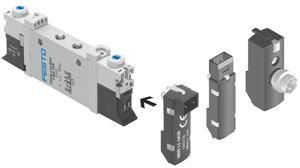

The valve’s electronics can be replaced in a one-click operation. The housing remains the same, only the connection is changed. A wide range of variants can be fitted, with connection options that include M8 and stranded wire.

Related articles: