Drives control world`s longest conveyor belt

A 19km-long conveyor belt supplying coal to an aluminium mill in Texas

– thought to be world’s longest single-belt system – has been equipped with an efficient drive-based control system which can adapt to different loads.

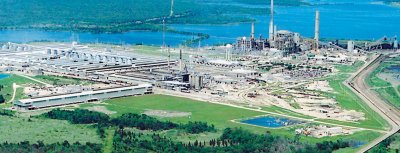

The belt is part of a 32km link that takes brown coal from the Three Oaks mine to a power station at Alcoa’s Rockdale mill (shown above). The 19km-long belt forms the critical central section of the transport route, parts of which pass over uneven terrain. It links the point where the material comes out of the open-cast mine to the point from which it is taken to the power station.

The belt is being controlled by five 556kW Siemens Simovert Masterdrive VC drives, with one drive at the loading point, two in the middle of the route, and two at the unloading point, linked by fibre optic cables.

The control system prevents the belt from oscillating during starting and stopping and is said to use much less energy than conventional uncontrolled belt drives. The drives are first powered up to 10% of full speed and, after a stabilisation phase of up to two minutes, the system is accelerated to full speed.