Ionetic plans to use Rockwell's automation hardware and control systems, as well as software such as Emulate3D, to build digital twins of its production facilities and manufacturing execution systems (MESs). This simulation and modelling will enable Ionetic to generate detailed requirements for a flexible, modular production facility.

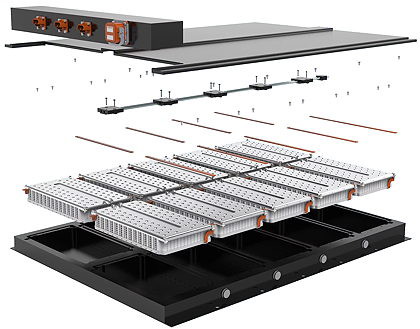

Ionetic says that its Arc battery platform can cut the cost of developing automotive battery packs by 90%. Combining software and hardware, it standardises materials, geometries and more, allowing all battery packs to share a common foundation, while being tailored to the needs of individual customers. Combined with the flexible manufacturing system that it is developing, Ionetic believes that it can deliver class-leading speed and cost-to-market.

Each battery pack can be produced in a different shape, size, energy or voltage rating, and be optimised for high energy, long life or high performance. Ionetic’s current architecture is capable of achieving energy densities of up to 245Wh/kg at the module level, while also promising racing-specification performance.

“We're confident that [Ionetic’s] unique technology and approach to battery-pack design will make the EV market accessible to a greater range of automakers than before, helping the UK and Europe to meet both climate and industrial goals,” says Asa Arvidsson, vice-president of Rockwell’s north region. “We're excited to support Ionetic with our unique suite of automation and digital technologies.”

“This new partnership with Rockwell Automation gives us the production and automation expertise we need to get up and running, and then scale, fast,” adds Ionetic’s chief manufacturing officer, Stephen Large. “We're excited to partner with a world-leader in manufacturing technologies to build digital twins of our facilities and utilise decades of expertise to grow Ionetic.”

The cost of developing EV batteries for new vehicle designs is prohibitive for all but the largest volume car-makers. Ionetic believes that this could prevent many successful, long-standing OEMs from entering the market. Its technology is intended to overcome this obstacle.

Ionetic’s modular battery technology is being developed to allow smaller manufacturers to enter the EV market

Ionetic is creating a one-stop-shop for battery-pack design, testing and manufacture. It plans to work with EV start-up OEMs to cut the cost of EV battery development.

“We see Rockwell Automation as a long-term partner and anticipate our relationship will enable our evolution and expansion long into the future as the EV battery market grows exponentially over the next decade and more,” says Ionetic’s CEO and co-founder, James Eaton.

Ionetic: LinkedIn

Rockwell Automation: Twitter LinkedIn Facebook