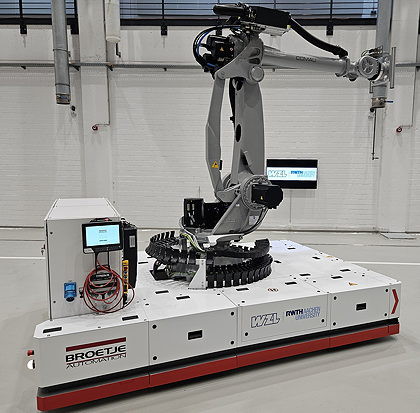

The researchers, from the Laboratory for Machine Tools and Production Engineering (WZL) at RWTH Aachen University, argue that traditional robots anchored to the floor have to operate within a restricted workspace. Although mobile cobots (collaborative robots) do exist, their payloads are usually limited to around 8kg.

If large robots were able to move freely between assembly stations, the resulting unlimited workspace could provide flexibility and allow resources to be deployed more strategically, the WZL researchers argue. The robots could also perform some of the tasks currently handled by AGVs (automated guided vehicles) and AMRs (autonomous mobile robots).

The researchers plan to use their large robot to conduct research in areas such as planning simultaneous movement of the manipulator and the base, which has not been possible until now. They believe that such “holistic” motion planning, will allow mobile manipulators to be deployed with 25% faster execution times.

As well as the mobile platform, Broetje-Automation has supplied modular software based on the Robot Operating System 2 (ROS2), allowing the researchers to develop new algorithms, and opening up possibilities for innovative approaches to robotics and assembly research.

The mobile robot uses multiple sensors to perceive its environment and to operate autonomously. In future, it will be integrated into an existing 5G campus network and will be capable of communicating wirelessly in real-time with other robots and factory cloud systems. A hybrid Siemens control system will allow the mobile robot to be controlled in real-time using a Linux-based operating system.

WZL’s large mobile robot could pave the way to more flexible production lines of the future

“The large robot is unique in its 5G connectivity, payload capacity, ROS control and mobility. Our nickname for it is Snowflake,” says Dr-Ing Amon Göppert, chief engineer at WZL’s Chair of Production Metrology and Quality Management. “With this, we can implement new automated assembly processes for large components and address the automation gap in the industry.”

The researchers believe that the mobile robot could be a key element of future “lineless mobile assembly systems” (LMASs). These abandon spatial and temporal rigid chaining of individual assembly systems, allowing (partial) mobilisation of resources on production floors following a “clean floor” approach. In an LMAS, AMRs and autonomous mobile manipulators (AMMs) take over the transportation tasks and, in the case of AMMs, can even perform assembly steps. WZL’s large mobile robot could increase manufacturing productivity, despite conditions that can change.