As the joint winner of ABB’s Power Density Start-up Challenge 2023 for Motor Drive Products, QPT will collaborate with ABB in a project worth up to $30,000 with the aim of producing a commercialisation plan by the third quarter of 2024. The other winner was a Canadian company, Calogy Solutions, which is working on a low-cost technology for managing battery temperatures.

QPT was established in 2019 to solve the challenges of designing with GaN transistors, and to unlock the potential of GaN to provide substantial energy savings across a wide range of electrical devices.

Although GaN power semiconductors can, in theory, deliver significant energy savings over silicon and silicon carbide (SiC), they need to operate at extremely high frequencies of up to 20Mhz to deliver these savings and high power densities. But operating at such high frequencies creates electromagnetic interference, making it difficult to achieve the potential benefits.

QPT claims it is the only company that can run GaN transistors at frequencies up to 20MHz without EMI issues or overheating, thus delivering the promised benefits of GaN.

“Our technology enables drives controls to be made much smaller as we achieve the best power densities and efficiencies of any current technology by now enabling GaN to be hard-switched at 1 to 2ns,” explains QPT’s founder and CEO, Rob Gwynne. “Current VSDs are bulky which means that they are invariably located away from the motor itself and then connected by copper cables that are big and heavy to cope with the hundreds of Amps or so going through them and also waste energy in the process.

“QPT’s next-generation GaN technology shrinks the size of a VSD to around a twentieth of the size so that it can be integrated beside the motor,” he adds. “The need for big, costly filters that Si, SiC or slow existing GaN alternatives require, and preclude easy integration, is also eliminated further reducing the overall size which further helps integration.”

QPT says that it has already developed patented techniques for operating VSDs at PWM (pulse width modulation) switching speeds up to 2MHz, providing switching speeds of 1-2ns without any EMC issues. (Silicon and SiC transistors, by comparison, typically switch at 20-50ns.) The result is up to 80% less energy wastage in chopping processes compared to existing VSD designs.

QPT founder and CEO, Rob Gwynne, with one of the company’s GaN modules

QPT adds that its future products will switch even faster. The first generation has been designed to work with existing motor control chips which cannot operate faster than 2MHz. Drives-makers can replace existing silicon or SiC power stages with QPT’s GaN-based power modules to make their VFDs more efficient.

Another advantage that QPT claims for its technology is that unlike conventional VSDs, whose efficiency of around 97% drops off “rapidly” with speed, GaN-based VSDs have an efficiency of around 99% which hardly decreases at all with speed. At half-speed, traditional VSDs are typically 95% efficient, at quarter-speed 93% efficient, and at eighth-speed 88% efficient.

QPT suggests that its technology could produce integrated motors rated at around 75kW, which would allow energy to be recaptured through regenerative braking.

The only connections needed to the integrated motors would be a three-phase power cable and an optical fibre link for control. Conventional cables from separate drives (containing large filters) to motors would be eliminated, avoiding EMI issues, heat losses and the risk of damage.

The company envisages other applications including robots, servodrives, welding systems, as well as HVAC systems and electric vehicles. In servo applications, for example, GaN modules could boost productivity because they settle faster, allowing more moves to be achieved per hour.

QPT has recently opened a funding round on Crowdcube with the aim of raising £500,000. A pioneer of GaN technology, Geoff Haynes, who co-founded GaN Systems, is the lead investor for the round.

“The UK is renowned for innovation, so we wanted to provide people with the opportunity to invest in a new technology that makes electric motors more efficient,” says Gwynne.

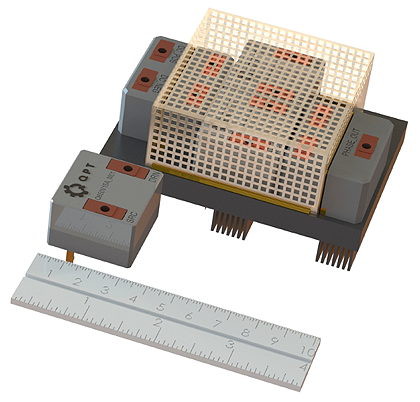

A 10hp (7.5kW), 230V three-phase drive based on GaN modules and incorporating a low-cost, low-loss, high power density sinewave flter. QPT claims that the combined drive/filter is about 100 times smaller than existing products and that its inrush currents are an order of magnitude smaller than most other drives. One of the drive’s modules is shown in the foreground.