The simulation is integrated into the company’s TIA Portal automation platform. No extra software tools are needed. Using the digital twin, the logical and functional aspects of the drive can be simulated identically to the real drives, while electrical, magnetic and mechanical aspects are modelled partially. The tool allows machine-builders to cut their use of resources and to optimise energy efficiency, leading to more sustainable machine-building.

DriveSim Advanced expands Siemens’ drives simulation portfolio which it launched in 2021 with Sinamics DriveSim Basic. The Advanced version is part of Siemens’ new Industrial Operations X interoperable portfolio of products and services for production engineering, execution, and optimisation. This portfolio is, in turn, part of the company’s Xcelerator digital business platform.

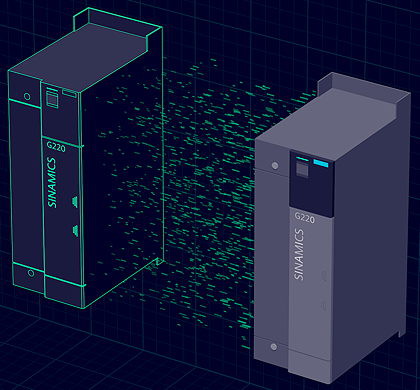

Siemens’ digital twin software provides realistic simulations of drives and their functions.

Siemens: Twitter LinkedIn Facebook