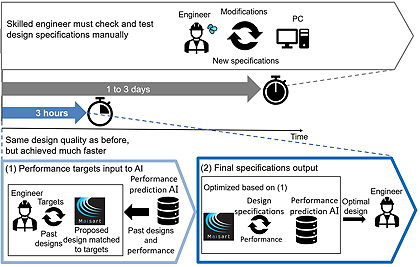

When designing motors, engineers usually adjust specifications repeatedly to balance performance against design – for example, efficiency against motor size. For engineers with limited experience, this often requires time-consuming trial-and-error testing, which must later be checked by skilled engineers.

When using the new system, engineers input performance requirements, and the AI (artificial intelligence) suggests the best specifications by referring to historical design data. The engineers then check the AI-generated specifications and adjust the targets in an interactive process that is repeated until the specifications satisfy the performance targets.

In tests of the new system, Mitsubishi says design times were cut from one day for experienced engineers (or up to three days for less experienced engineers), to just three hours. The results were as good as traditionally produced designs, it adds.

The system also helps to simplify and standardise design processes, because the AI can generate new specifications. Mitsubishi adds that the system will help to transfer design skills to less experienced engineers.

The conventional approach to motor design (top diagram) compared to the AI-assisted version (below)

TMEIC plans to adopt the the electrical motor-design support system internally and to commercialise it during 2024.

Mitsubishi Electric: LinkedIn Facebook