Niron’s magnets, based on iron nitrides, are also said to have other potential applications including industrial motors, fans, pumps, power tools, actuators and sensors. They have a similar performance to rare-earths, but cost less and exhibit better stability at high temperatures.

Unlike most existing wind turbine generators, which use radial-flux designs that depend on rare-earth magnets, GreenSpur is using an axial-flux architecture that does not need rare-earths. “Our patented concept can eliminate the risks associated with supply chain constraints and volatile pricing,” says the company’s commercial director, Andrew Hine.

However, while earlier versions of the GreenSpur’s generator which used ferrite magnets attracted interest, they were too heavy. Keeping generator masses similar to existing machines is vital, because adding weight requires stronger structural support for the turbine, increasing costs. Niron’s magnets offers much better magnetic performance than ferrites, resulting in an initial 56% reduction in mass for the GreenSpur 15MW generator. The design has yet to be optimised, so the final reduction could be higher.

A review of the new design by the ORE Catapult, supported by an Innovate UK grant, has confirmed that it now meets the mass and efficiency targets needed for the market. “We have worked with GreenSpur in support of their hugely innovative and disruptive technology for several years,” reports the Catapult’s director of technology development, Tony Quinn. “Although there was interest in a rare-earth-free solution, there were concerns that their generator would be too heavy.

“However, with Niron’s novel rare earth-free magnet, GreenSpur is able to show attractive mass and efficiency targets and a credible solution for consideration within a next-generation turbine,” he adds. “We are now helping GreenSpur and Niron to present this opportunity to OEMs, developers, and strategic investors. The aim is to create an industry consortium with the right combination of players to bring this offering to market.”

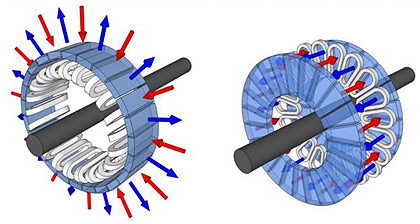

In GreenSpur’s axial-flux design, the rotor and stator are arranged as discs with magnetic flux flowing parallel to the axis. The machines are formed from modules, each containing a rotor with embedded magnets, sandwiched between two coil-containing stators in which currents are induced. Axial flux designs are easier to cool and allow larger air gaps between the rotor and stator than radial designs, simplifying manufacturing and allowing greater tolerance for movement under load. GreenSpur claims to have overcome two of limitations of axial-flux designs – difficulties with manufacturing the stator laminations and inner coils, and a tendency for cogging at low speeds.

The arrangement of magnets in in radial (left) and axial (right) machines showing the resulting lines of flux

Niron’s iron nitride magnets are based on low-cost, sustainable materials and are temperature-stable without needing heavy rare-earth dopants. The company says that they break the compromise between neodymium and ferrites, with magnetic and material properties that deliver performance and efficiency from a clean, stable and low-cost supply chain. Investors in the technology include Volvo and the data storage specialist Western Digital.

“Our Clean Earth Magnet technology helps eliminate reliance on expensive, supply constrained, rare earth-based magnets, without compromising on performance,” says Niron Magnetics’ CEO, Andy Blackburn. “Device designers and manufacturers take our technology and realise its impact. By working with GreenSpur, we have been able to demonstrate what can be achieved with our Generation 1 technology in wind applications, with innovative materials and innovative device design coming together to enable a potentially transformative solution for the offshore market.”

It has been predicted that the world’s offshore wind capacity could reach 1,400GW by 2050 and will be crucial in the transition to net-zero emissions. But the current reliance on expensive, supply-constrained rare earth magnets is a barrier to progress. Demand for rare-earth materials could outstrip supply by the mid-2030s. A single existing wind turbine generator can need as much rare-earth materials as 1,000 electric vehicles.

“The risk that the rare-earth magnet supply chain poses to international offshore wind is existential,” says Hine. “For the first time, we have a path that takes this risk out of the equation.”

Niron Magnetics: LinkedIn