The modular drive system incorporates sensors and thermal management technologies that make it particularly suitable for precision robotics applications.

The modular design allows the hardware to be configured to suit the application. There are three main variants:

• the Tuaka Active, consisting of a motor and gearbox, with a rated torque output of 21-67Nm (44-157Nm peak) and a top speed of 123 rpm;

• the Tuaka Servo, which adds a choice of encoders, including EnDat 2.2 and Hiperface types; and

• the Tuaka Drive, which also incorporates a drive and safety functions.

The Drive version can optionally be configured with a torque sensor as well as a second encoder on the output, without increasing its size. It supports safety functions up to SIL3 / PLe.

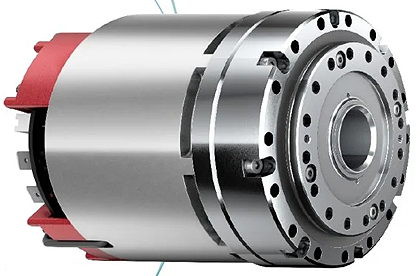

The Drive version of Sumitomo’s award-winning modular actuator system consists of a motor, gearbox and drive with safety functions

Professor Reimund Neugebauer, chairman of the Hermes Award jury, says that the Sumitomo drive “is not just technologically impressive: the fully integrated drive for robotic applications and automation technology is suitable for high-precision, sensitive applications in service robotics as well as for interaction with humans. Furthermore, the modular concept and building block systems enable the necessary hardware to be configured to the specific application.”

Sumitomo Drive Technologies: LinkedIn