Mitsubishi says that restrictions resulting from the Covid-19 pandemic have made it difficult for manufacturers to install and maintain production facilities. At the same time, the manufacturing sector has been seeing a growing demand for the digital transformation of factories. These trends have highlighted the use of digital technologies to solve issues and the new tool is intended to streamline processes by using digital techniques to simulate the operation of production facilities before they are built.

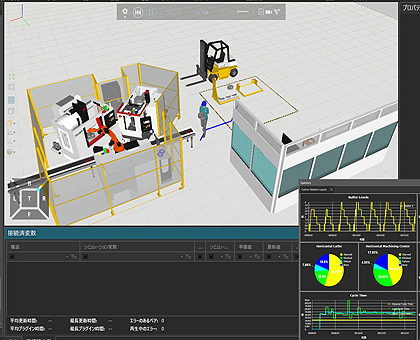

The PC-based tool connects to industrial hardware and software to help visualise and simulate manufacturing work processes ranging from designing production facilities, to eventually operating and maintaining them. The system supports around 2,500 types of production equipment including robots, conveyors and processing machinery, which can be combined in simulated 3D production environments using simple drag-and-drop operation. Various parameters can be set on 3D screens to alter the layout of the production lines.

The tool connects to simulators, which are available separately as part of Mitsubishi’s Melsoft iQ Works software, to replicate the control of devices such as PLCs and servo-based motion controllers. If an error is found during the verification process, engineers can check the status of planned production facilities by viewing PLC sequence programs, or by looking at displays of operational waveforms and/or video data.

The tool connects directly to the Melsoft simulators and factory devices without needing to go via an OPC server. According to Mitsubishi, this allows 3D data to be updated about 12 times faster than would be possible in an OPC environment. Detailed checks for possible operational interference can also reduce the need for reworking, as well as helping to improve quality.

During the operation and maintenance phases of a plant, the Melsoft Gemini tool presents information to the line operators to help them determine the causes of any abnormal events.

Mitsubishi’s 3D simulation tool can verify the performance of production lines digitally before they are built

The software can produce line, area, bar and circle graphs to help visualise and analyse simulation data for various rates of production, thus helping to design efficient production lines. Equipment status, the durations of production tasks, worker waiting times, and other parameters can be quantified statistically and displayed as graphs to identify different production yields and operating rates, allowing lines to be designed and upgraded efficiently.

The tool is expected to be available at the end of April 2022.

Mitsubishi Electric: LinkedIn Facebook