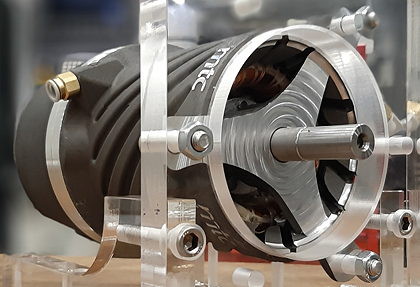

The team, from the Centre’s National Centre for Additive Manufacturing, along with its electrification experts, believe the MTC is one of the first organisations in the world to achieve this. Although a 3D-printed motors have been the subject of theoretical studies in the past, they have not yet reached commercial reality.

The MTC team says it has cleared a path for producing motors using additive manufacturing (AM) techniques. It has already developed a way of making motor casings that incorporate cooling channels using these techniques, and is now aiming to produce entire motors using AM.

“Additive manufacturing is a key enabler for developing the complex features and forms essential to improving the performance and functionality of electric motors,” explains the MTC’s chief technologist, Steve Nesbitt. “The process of manufacturing electric motors has a number of challenges including complex or manual assembly, materials that are difficult to process and which can be expensive, thermal management, and the need to make the assembly lighter.

“By leveraging the capabilities of additive manufacture through product redesign,” he adds, “major benefits can be achieved in costs, waste reduction, performance and ease of manufacture.”

The MTC team is now investigating further developments required for commercial production, with the aim of overcoming potential challenges and constraints.

The motor that the MTC has produced using 3D printing techniques has fewer components, and they are lighter and smaller

The MTC, located in Coventry, was founded by the Universities of Birmingham, Loughborough and Nottingham and the research organisation, TWI (The Welding Institute). The Centre aims to provide a competitive environment to bridge the gap between university-based research and the development of innovative manufacturing systems, in line with the UK Government’s manufacturing strategy. Its industrial members include leading manufacturers.

National Centre for Additive Manufacturing: Twitter LinkedIn