The software offers quick and easy entry into the simulation of drive technologies and allows machine and plant manufacturers to accelerate their development programmes. It focuses on simulating user applications including components that interact with a drive.

The simulations can answer questions even before drive products have been chosen. The models provide detailed representations of drive systems, allowing virtual commissioning of PLCs with known Profidrive telegrams or complex mechanics on virtual driveshafts.

One potential application is the coupling of PLCs and mechanical models. The calculated load profiles can be loaded into Siemens’ TIA Selection Tool or Sizer software to help choose an appropriate drive. The simulation can access drive parameters and interfaces. Users only need to configure the part of the drive required for simulation purposes.

Time-consuming virtual commissioning of complete drive systems is not necessary, saving time and costs. The models in the simulation link to drive documentation and have been validated against actual Sinamics drives using the same test vectors.

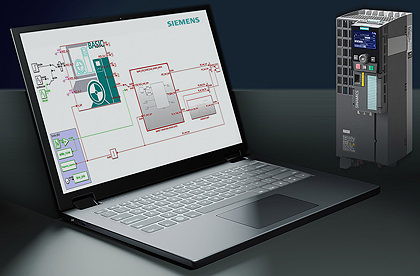

Siemens says that its Sinamics DriveSim Basic simulation tool bridges the gap between logical and mechanical simulation

The Sinamics DriveSim Basic tool is available as a standardised FMU (functional mockup unit) model, and offers the same FMU file for every Sinamics drive. Initially, it can be used to represent Siemens’ Sinamics S120 and G120 drives, including attached motors. It will be extended to include other drives.

The FMU can be imported into commercial simulation programs such as Simit, Simcenter Amesim, NX Motion or Matlab Simulink. Together with other Siemens virtual tools – such as Simatic S7 PLCSIM Advanced or NX Mechatronics Concept Designer – it allows consistent model-based development processes to be implemented.

Siemens: Twitter LinkedIn Facebook