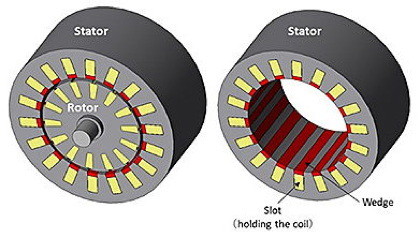

The material is designed to be used in stator wedges, particularly in mid-to-large-sized induction motors. These wedges prevent motor coils from falling out of their slots. They were traditionally made of non-magnetic materials, but using a magnetic material instead has been found to guide magnetic flux towards the wedges, improving energy efficiency.

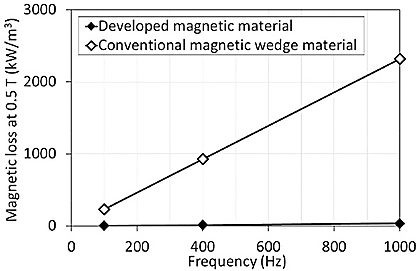

But the magnetic materials previously used for wedges contained spherical magnetic metal particles and could not control the magnetic flux sufficiently, resulting in the flux leaking in unwanted directions. These materials also suffer from high magnetic losses and poor high-temperature performance, making them unsuitable for applications that require high heat resistance – such as traction motors for trains, for example.

The new material is composed of flaky magnetic metal particles with different magnetic properties depending on the direction of the magnetic field. They also exhibit extremely low magnetic losses. When used as wedges, the material can guide magnetic flux effectively in the required direction, cutting energy losses and improving energy efficiencies “significantly”.

The Toshiba researchers also found that by compacting the flaky magnetic particles with a heat-resistant binder they could improve the material’s thermal stability, even when operating at 220°C for extended periods. This heat resistance widens the potential applications for the wedges to include industrial equipment, cars, robots and medical systems.

The new material is designed to be used in stator wedges to control the flow of magnetic flux in a motor

Simply by replacing existing motor wedges with similar components made of the new material, Toshiba says it has significantly improved energy efficiencies, without needing to change motor designs. When the wedges were used in railway drive systems, for example, an efficiency increase of 0.9% was achieved, with the induction motors approaching the efficiency of permanent magnet synchronous motors. The material could also be used in PM synchronous motors to achieve even higher efficiencies.

The railway sector will be one of Toshiba’s first target markets for the new material.

The reduction in losses achieved using the new material increases with frequency