The flexible, scalable system uses standardised modules with many customisation options, allowing actuators to be tailored to particular applications, such as metal pressing, wood and paper milling, marine technologies, mobile machinery, and plastics injection and blow-moulding machines.

Among the advantages that Moog claims for the technology are:

• the use of fewer components, reducing the risk of breakdowns and making maintenance quicker and easier;

• a decentralised design that eliminates the need for large hydraulic power units, and reduces piping;

• four-quadrant operation for effective energy management, with reduced consumption due to energy recovery; and

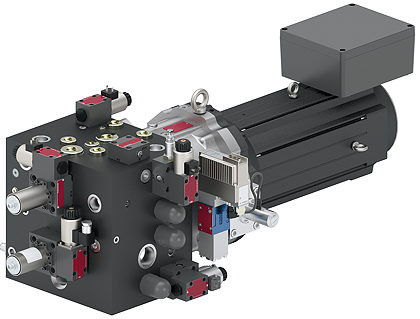

• a low-inertia electrohydrostatic pump unit (EPU), that results in high system dynamics.

Moog claims that its modular electrohydrostatic actuator technology uses up to 90% less oil than standard electrohydraulic systems

The smallest version of the actuator consists of a basic manifold and an EPU delivered as an assembled and tested system. This can be combined with various options, or adapted using additional standardised high-speed manifolds, to build complete motion control systems. The localised power system improves energy efficiency by eliminating flow control valves and centralised piping, and reduces the amount of energy wasted in traditional hydraulic systems.