The new six-axis IRB 1300 robot has been designed and built in China to help meet the demand for faster, smaller robots that can rapidly lift heavy objects or loads with complex or irregular shapes. It is 60% lighter, with an 83% smaller footprint and 27% faster cycle time than the previous IRB 1600 model.

The robot will be available in three load/reach combinations: 11kg/0.9m, 10kg/1.15m, and 7kg/1.4m, with the 11kg variant said to offer the highest payload of any robot in its class. With each robot occupying 220 x 220mm of floor space, more can be deployed in a given area.

ABB used the Chinese exhibition to showcase technologies that could be used in hospitals of the future, including a pharmacy automation system incorporating a robotic bin-picking system. The expandable, modular system, developed in conjunction with Shanghai Seventh People's Hospital, can handle the workload of two pharmacists. A MiniLoad system using an IRB 2600 robot stores an retrieves medicines, while an IRB 1200 robot with 3D vision and AI technology sorts and dispenses the medicines to fulfil prescriptions. ABB’s Ability digital platform can be used to manage the pharmacy, ensuring 100% traceability.

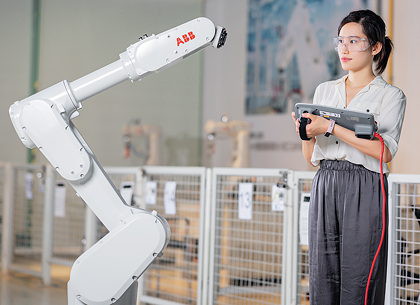

ABB claims that its IRB 1300 robot offers the highest payload in its class

ABB also demonstrated a collaborative cell for medical laboratories based on a dual-arm YuMi collaborative robot that can operate alongside lab workers on tasks such as pipetting, liquid handling, compounding and microbiological culturing.

“Automation has never been more relevant than it is right now and we are pushing the boundaries of technology to energise and transform a wide range of industries with more than a dozen robotic products and solutions all designed to help our customers adapt to a rapidly changing business landscape,” says Sami Atiya, president of ABB’s Robotics and Discrete Automation business.

ABB is currently building a “robotics factory of the future” in Shanghai, which it claims will be the world’s most advanced, automated and flexible robotics plant. The production and research facility, due to open in 2021, will include self-learning machines and “will push the boundaries of automation and bring flexible manufacturing to the next level,” according to ABB.