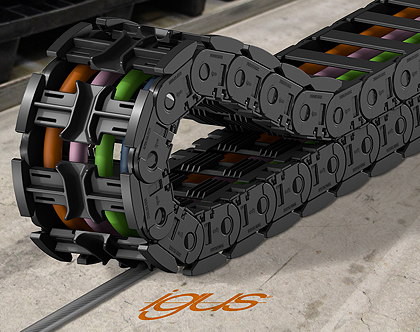

Instead of a conventional guide trough, the new system is guided by a steel rope that is held in place by grooves in the chain’s outer radius. The maintenance-free system can be installed in less than hour and can carry both power and communications cables. Alternatively, the chain can be guided using a plastic rope or profile.

Major drawbacks of conventional busbar technologies include their high maintenance costs, their need for regular cleaning to avoid contact faults, and the fact that can usually be used only for power transmission,

“The autoglide 5 can easily be installed in the aisle on a rope or a profile,” explains Christian Strauch, igus’ intralogistics industry manager. It offers “a real alternative to the busbar systems,” he adds.

Unlike busbars, the new e-chain system has no open contacts, and is said to be easy to clean.

To install the new energy chain, the metal rope is first stretched on the floor. The underside of the chain links incorporate a guide element that allows the chain to rest safely on the rope.

Igus’ trough-free energy chain system offers a low-cost alternative to busbars and can be installed in less than an hour

To achieve wear-resistant and precise gliding of the upper and lower runs of the chain, the system uses comb-like injection-moulded crossbars that prevent the energy chain from slipping out. It is this design that avoids the need for a guide trough.

Conventional busbar systems – or pantograph contacts – are susceptible to wear and may need be replaced after only one to two years. igus believes that its new e-chain, made from high-performance polymers, will provide a durable, maintenance-free energy supply system. It is currently testing the service life of the chain in its laboratories.

The lab tests have already shown that the new system operates quietly – at 2m/s, the measured noise level was 63dB(A).

Igus will be offering the autoglide 5 system harnessed as a readychain containing flexible chainflex cables.