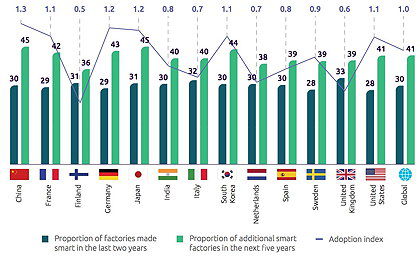

According to the report – based on a survey of more than 1,000 industrial company executives in 13 countries – China, Germany and Japan are leading the world in the adoption of smart factory technologies, followed by South Korea, the US and France. The UK is in 12th position, with only Finland being lower.

The report, called Smart Factories @ Scale, says that just 14% of organisations that have already embarked on smart factory initiatives regard them as having been successful, with nearly 60% saying that they are struggling to scale their operations. It identifies the two main challenges: IT-OT convergence; and the range of skills needed to drive the transformation.

But the report also highlights how the technology-led disruption leading to “intelligent industry” will present opportunities for manufacturers looking for new ways to create value, optimise their operations and innovate for a sustainable future. It says that about 10% of the companies that it interviewed have already digitalised their industrial systems successfully, and invested in areas such as digital platforms, data readiness, cyber-security, talent and governance. Other organisations need to learn from these “front runners”, the report suggests.

Since Capgemini last surveyed the smart factory scene two years ago, it finds that organisations are showing “an increasing appetite and aptitude” for digitalisation. More companies are progressing with smart factory initiatives and one-third of factories have already been transformed with some degree of smart facilities, according to the study. In the coming five years, the organisations quizzed plan to create 40% more smart factories and to increase their annual investments in this area by 1.7 times, compared to what they have been spending in the past three years.

The percentage of factories that have been transformed into “smart” operations in the past two years, and future expansion plans (shown by the adoption index), by country. An index above one shows that the country has more aggressive expansion plans than average.Source: Capgemini

The report predicts that 5G will become a key enabler of smart factory initiatives because it will provide manufacturers with the opportunity to introduce or enhance a variety of reliable, real-time applications.

“To unlock the promise of the smart factory, organisations need to design and implement a strong governance program and develop a culture of data-driven operations,” suggests Jean-Pierre Petit, Capgemini’s director of digital manufacturing. “The move to an intelligent industry is a strategic opportunity for global manufacturers to leverage the convergence IT and OT to change the way their industries will operate and be future-ready.”