The materials could be used in electric motors, for example, to avoid the corrosion caused by electric currents crossing gaps between components. This phenomenon can cause sparks or stray currents, resulting in hardware pitting and carbonisation of lubricants. Electrically conductive seals or bearings could prevent such issues by creating conductive paths between components, thus grounding the motor system.

The new materials have been developed at Trelleborg Sealing Solutions’ plant in Helsingør, Denmark. The company claims that they are the only PTFE (polytetrafluoroethylene) based electrically conductive materials designed for use in spring and elastomer-energised seals. They have been engineered specifically for use in dynamic applications involving seals and bearings.

Although conductive plastics already exist, they have limitations, as Trelleborg’s development manager, Soeren Roepstorff, explains. “Conductive elastomers are available,” he says, “but these are primarily only for static applications, while the conductive, injection-mouldable plastic materials that exist have low flexibility and are less suited for sealing purposes and for installation in closed grooves.”

Konrad Saur, Trelleborg’s vice-president of innovation and technology, calls the new materials “unique”, adding that they have been “specifically developed for use in spring and elastomer-energised seals, as well as bearings, in response to a strong market demand to support electrification of drives, eMobility, sensing and IoT solutions”.

PTFE is naturally an good insulator but, by adding conductive carbon fillers, composites can be produced that can conduct electricity. This capability was discovered by accident and reducing electrical resistance was not the main aim when developing these materials.

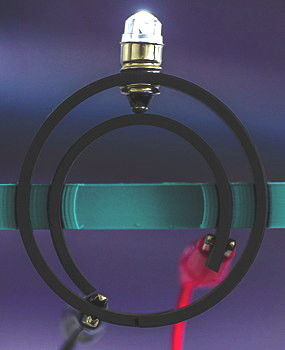

Trelleborg’s conductive sealing materials can provide reliable electrical connections between moving parts

The new materials – called Turcon MC1 (for medium-to-high conductivity) and MC2 (for high-conductivity applications) – were developed specifically to conduct electricity in dynamic sealing applications and their sealing performance has been optimised. Tests have shown that they exhibit high conductivity even with low contact pressures and when running in oil.

In addition to their potential use in motors, the new materials could transmit signals to or from sensors, enabling manufacturers to develop more complex systems incorporating aspects of artificial intelligence without adding electrical circuitry.

Another potential application is to tackle the build-up of static in planes as they fly. Electrically conductive seals in landing gear could dissipate electricity or static safely.