The pump uses hydraulic oil as a lubricant for the gear teeth. Existing connections in the motor and the pump allow the oil to be returned to the circulation system, with the leakage flow lubricating the gear teeth constantly. This avoids the need to lubricate the teeth – normally done after around 3,000 operating hours. Machines can thus operate without interruption, boosting productivity.

The ability to control the drive and its low energy consumption, especially with partial loads, results in an efficient yet economical, system aimed, in particular, at plastics and casting applications.

Existing bores can be used for pressure sensors to monitor the lubrication of the internal teeth, simplifying predictive maintenance. Data from these sensors can minimise the risk of breakdowns, and allow machines to be serviced at set intervals.

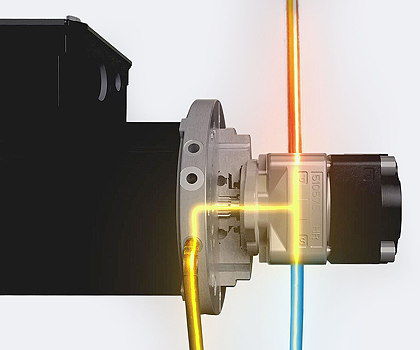

Baumüller says that mounting a hydraulic pump on a servomotor reduces the need for maintenance

Because the servo-pump has connecting holes on both sides, it can be installed horizontally or vertically, depending on the application. It is based on Baumüller’s DSD2 three-phase synchronous motors and is available initially in sizes 71 and 100, with a size 132 version due soon.