The Simotics iQ technology uses a small sensor box mounted on a Simotics SD LV motor to capture operating and condition parameters and transmit them by WiFi to Siemens’ MindSphere cloud-based IoT operating system. The data can be stored and analysed there by the Simotics IQ MindApp to provide analytical results on the operation and condition of the motor. It can suggest preventive maintenance measures and help to boost productivity, according to Siemens.

At SPS, Siemens will demonstrate a Simotics SD motor connected to MindSphere. It says that the data analytics will enhance process transparency, allowing key performance indicators, such as temperature or transient oscillations, to be analysed and displayed, giving users the ability to react early to potential problems. By applying configurable warning limits and intelligent analytics, they can plan their maintenance activities in good time and act before the motor fails.

By integrating several motors, the Simotics IQ MindApp can not only provide condition monitoring functions, but also manage them in terms of energy consumption or maintenance scheduling.

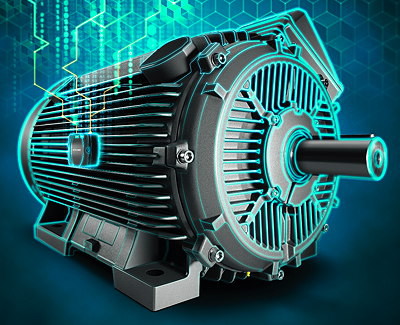

A Simotics SD LV motor fitted with an iQ sensor box.

Siemens Simotics iQ system is the latest in a series of similar motor-monitoring technologies, including ABB’s Ability Smart Sensor.