Teco’s upgraded plant uses technologies such as robots, 3D vision systems and automated guided vehicles. The number of workers needed in the plant has been reduced from 60 to 20, and output has increased from 10 motors per worker per day, to 34.

Teco has also signed an agreement to produce equipment for the Finnish heavy-duty drivetrain expert, Visedo, which has developed a technology called SRPM (synchronous reluctance assisted permanent magnet), which, it claims, is more efficient than drivetrains based on conventional induction or permanent magnet motors. The technology can be used in hybrid or fully electric drives for marine vessels, road vehicles and heavy-duty machinery.

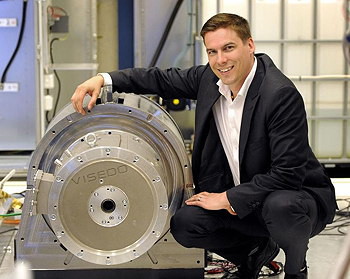

Visedo CEO Kimmo Rauma predicts that the technology will disrupt the market for large electrically-powered vehicles.

Visedo CEO Kimmo Rauma: Teco deal will make it easier to compete on scale and volumePhoto: Johannes Wiehn

“The revolution to electrify the world’s transport and transition away from diesel reliance is already underway,” he says. “But, until now, the industry producing powertrains for heavy-duty electric vehicles and machines has been dominated by AC induction.

“Our SRPM technology allows Visedo to deliver the market’s most efficient hybrid and fully-electric solutions that are also smaller and lighter than our competitors,” he continues. “Visedo can already guarantee better performing hybrid and fully electric drivetrains in a more compact and robust product – our partnership with Teco will allow Visedo also to compete at the scale and volume of our tier one OEM rivals.”