Sick says that the real-time digital interface has made single-cable servomotor connections reliable. The company has now decided to make the previously proprietary interface available as an open protocol, and predicts that the move will reduce the number of servodrive interfaces in use.

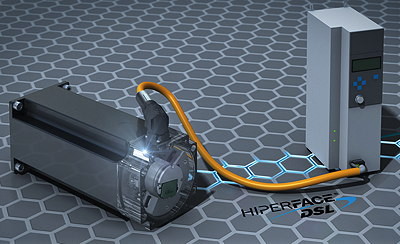

Hiperface DSL transfers data between servodrives and motors over two wires in cables that can be up to 100m long. It can also transfer signals from other sensors integrated into the digital motor feedback protocol. The signals are protected from disturbances caused by the motor’s power cables by the use of pulse transformers and other measures.

The technology supports the use of electronic “labels” for automatic drive configuration. Motor specifications, serial numbers and part numbers, as well as other data, can be used to adapt the drive automatically to the motor parameters. The digital interface can also be used for condition-monitoring of machines.

“Creating an open interface is the logical next step in the phenomenal success story of Hiperface DSL,” says Darren Pratt, Sick’s encoder product manager in the UK, “especially as manufacturers move towards Industry 4.0-enabled production environments.

Sick predicts that opening up its Hiperface DSL technology will reduce the number of servodrive interfaces on the market

“By opening up the proprietary interface, Sick will make Hiperface DSL an open-market standard,” he adds. “Already, major manufacturers have accelerated integration of Hiperface DSL digital feedback capability into their product development. In turn, OEM machine-builders have been able to optimise costs and space utilisation in their machines.”

According to Pratt, “machine users have benefitted from an improvement in plant availability due to the reduction in failure points and the extensive condition-monitoring capabilities of systems using Hiperface DSL.”