GE says that the system offers a next-generation platform for the age of the Industrial Internet. It allows users to connect their assets to GE’s Predix industrial operating system within 15 minutes. It extends down to the level of individual controls to optimise outcomes, powered by a computing capability said to be 100 times more powerful than standard control systems. It also allows users to develop their own apps powered by Predix.

“IICS was designed to help our customers meet the demanding challenges they face every day in running their organisations with increasing efficiency,” explains Jim Walsh, president and CEO of GE Automation and Controls. “With IICS, we’ll be helping customers to get more out of their assets – more productivity, more reliability and more profit.”

The system uses GE’s Field Agent technology as the gateway between assets and the industrial Internet. This rugged, pre-configured technology collects and conveys data securely from machines and feeds this into analytics that help to improve operations.

The IICS includes:

• Outcome optimising controllers These offer real-time control and defence-in-depth security. They are also said to decrease time-to-market, to help reduce unplanned downtime, and to enhance system performance.

• An industrial cloud platform This provides real-time process optimisation and control, minimising disruption to applications, and creating new value without having to retrofit.

• Secure cloud connections These provide secure data collection and enable advanced analytics.

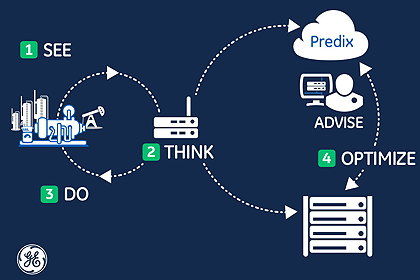

How IICS works. (1) It takes in information about the state of a controlled process through input modules. (2) It computes what the equipment or process should do next. (3) It outputs a set of instructions to actuators. (4) It refines asset behaviour in response to dynamic conditions and business objectives. The system executes deterministically in near-real-time (every 10ms) with the "optimise" loop executing over longer periods.

• Mix-and-match I/O The modular, scalable system provides remote, real-time diagnostics, and supports a wide range of communication options. It is said to improve availability and simplify maintenance.

• Intelligent, secure apps These apps – supplied by GE or defined by customers – run in the Cloud or at the Edge and offer functions such as rapid, preconfigured data visualisation.

• Professional services These services – including installation support, data modelling and analysis, and remote monitoring – reduce time-to-market, help to avoid unplanned downtime, and enhance system performance.

GE says that the technology builds on its RX3i and Mark Vie industrial control systems, which are embedded in industrial environments around the world, to create a next-generation platform for the age of the Industrial Internet.

It is offering dual- or quad-core configurations that provides safe and secure communication with either cloud-based or locally-hosted algorithms and applications.