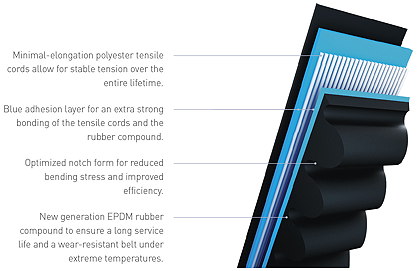

Unlike conventional V-belts, the new bandless V-belt does not suffer from severe tension decay in the first hours after installation. It uses minimal-stretch cords to maintain a stable tension over its entire lifetime.

The belts are made of the high-performance EPDM synthetic rubber compound. Although Gates used this material in its previous generation of Quad-Power belts, the company says it has optimised the construction to provide V-belts that last longer and offer high resistance to wear, even under extreme temperatures.

The second-generation EPDM belts are claimed to withstand the widest range of temperatures in the market. They maintain their performance in temperatures as low as –50°C, and resist hardening to avoid cracking in temperatures as high as +130°C.

The belts’ bandless, moulded-notch construction is said to ensure consistent pulley-to-belt contact, resulting in energy efficiencies as high as 98% – or 3% higher than wrapped V-belts.

The multilayer construction of the Quad-Power 4 belts ensures long operating lives without the need for servicing

The Quad-Power 4 belts are also available in a PowerBand construction for high shock-loaded or vibration-prone drives. A high-strength tie-band joins two or more belts permanently to provide lateral rigidity and to allow all of the strands to work together. This keeps the belts running in a straight line in the pulley grooves and eliminates jumped, flipped, tangled or separated belts.

Free samples of the new belt are available via Gates’ Web site.