The patented device is designed to control the speed of boxes and plastic trays travelling along gravity roller conveyors and spirals, or the end sections of sorters. It ensures that items weighing 0.5–35kg move smoothly along the conveyor, while limiting the speed of heavier items. It is aimed at applications such as warehousing, e-commerce, postal services, food and pharmaceutical operations, and for customers that use flow racks for heavy containers.

Gravity roller conveyors are often used to handle the final stage of goods moving through sorting systems. But they can incur costs if, for example, goods are damaged because they are moving too quickly, or time is needed to pick up stuck goods.

Most gravity conveyors have limited functions and, to minimise costs, their speed cannot usually be controlled. Interroll saw a need to develop a way to control their speed because of the increasing diversity in the size and weight of goods being carried by gravity conveyors.

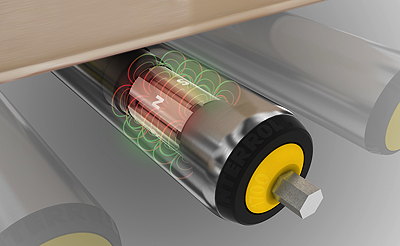

Interroll is using a built-in eddy current brake to control the speed of gravity roller conveyors

“Our MSC 50 is a solution with an optimum price-to-performance ratio,” says Ralf Garlichs, the company’s executive vice-president of products and technology. It is the only one of its kind using a maintenance-free eddy current brake. Double shielding prevents any magnetic emissions.

Because of its bi-directional braking capability, the device cannot be mounted incorrectly. It can be retrofitted to existing gravity conveyor installations.

The MSC 50 is designed for maximum loads of 500N and a maximum infeed speed of 2.5m/s. It can handle up to 3,000 items an hour. It has an temperature operating range of 5–40°C and is available in roller lengths from 210–1,400mm.