The Simotics reluctance motors, based on Siemens’ 1LE1 platform, will be available with aluminium frames for general-purpose duties (Simotics GP) or cast-iron enclosures for more aggressive operating conditions (Simotics SD). They will be part of Siemens’ Integrated Drive Systems (IDS) portfolio.

The motors are designed to be used with Siemens’ Sinamics G120 converters which incorporate vector control designed specifically for reluctance motors. The identification of the pole positions prevents jerking movements of the drive on activation, while a flying restart function allows synchronisation with a running motor. Predefined parameters in the form of a code on the motor nameplate are said to simplify the commissioning process.

The synchronous reluctance principle means that motor speeds remain constant, while the sensorless vector control is said to optimise performance. Both features enhance controllability of the drives. Ramp-up times are short thanks to the motors’ low inherent moment of inertia, combined with the vector control. Siemens says that low losses in the rotor will result in a high thermal utilisation of the motor. In terms of its design and handling, the motor is similar to the company’s 1LE1 asynchronous motors.

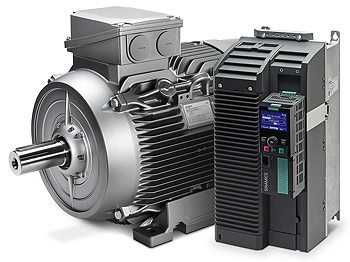

Siemens' synchronous reluctance motors are designed to be used with matching converters

The synchronous reluctance drives can integrated into automation environments via Profibus and Profinet interfaces. They are aimed at applications such as pumps, fans, compressors, mixers and centrifuges.