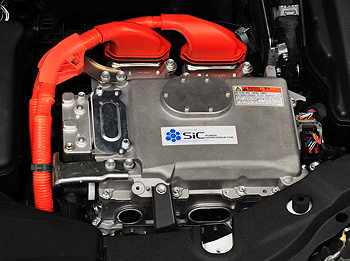

The SiC devices will be used in the power control units (PCUs) that supply battery power to the vehicle’s motors, and recharge the batteries using energy recovered during deceleration.

At present, most PCUs use conventional silicon power semiconductors, which are responsible for around 20% of a vehicle's electrical losses. SiC power semiconductors create less resistance when electricity flows through them, thus offering a promising way to raise powertrain efficiency.

One of Toyota’s test vehicles is a prototype hybrid Camry in which SiC transistors and diodes are being used in a voltage step-up converter and in the inverter that controls the vehicle’s drive motor.

During the year-long road trial, Toyota will gather data including voltages and currents, driving speeds and patterns, and conditions such as outside temperature. By comparing this data with data from PCUs using silicon semiconductors, it will assess the efficiency improvements.

Toyota will road-test its prototype SiC-based PCU for about a year

The other test vehicle is fuel cell bus that is already in operation. SiC diodes are being used in the step-up converter that controls the voltage from the fuel cell stack.

The SiC devices that Toyota is testing were developed jointly with Denso and Toyota Central R&D Labs as part of a broader r&d project in Japan.

Toyota says that it aims to put SiC power semiconductors into practical use as soon as possible.