The software is aimed at all types of machinery where motion is controlled by frequency inverters or servodrives. It includes 15 modules that perform tasks such as motion (positioning and synchronising), registration, cam profiling, temperature control and multi-conveyor co-ordination. The use of these modules makes programming easier and faster as developers become familiar with the program styles.

The autonomous modules contain machine motion and control functions. They can be chosen, exchanged and tested independently. The modules, available within the Lenze’s L-force programming environment, are low-cost – or, in some cases, free.

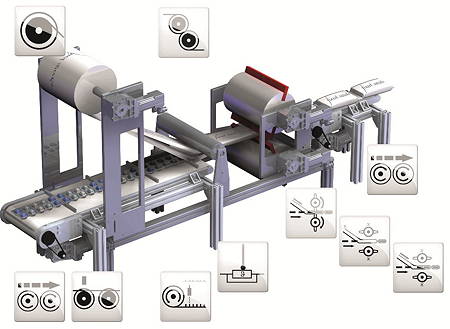

For example, a form, fill and seal packaging machine might need up to eight modules, including: tension control, cam profiling and registration for filling operation; temperature control; and motion for sealing and product spacing on the conveyor. Each module is self-contained, but can be integrated with others.

As well as cutting software development times by a factor of four, Lenze says that the software’s consistent structure helps to reduce programming errors.