Mitsubishi Electric Corporation has developed a multi-axis drive equipped with a silicon carbide (SiC) power module for controlling spindle motors and servomotors in CNC (computerised numerical control) applications. It says that the modules, which incorporate SiC diodes, exhibit much lower switching losses and are more tolerant of high temperatures than conventional silicon modules.

Mitsubishi has already commercialised SiC power modules for inverters used in air conditioners and rail vehicles. The new MDS-DM2-SPHV3-20080 SiC module for CNC drives is said to deliver higher speed and torque for driving machine tool spindles and servomotors, and is expected to improve productivity in factories.

The high-speed switching allows spindle motors to operate up to twice as fast as Mitsubishi’s previous model, the MDS-DM Series. And the lower power losses can lead to 15% more torque from spindle motors than the earlier drives.

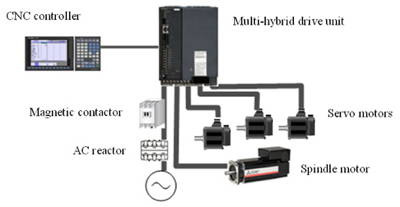

The “multi-hybrid” drives incorporate a Safe Torque Off function for shutting off the power supply to motors, reducing the number of magnetic reactors needed. A linear scale interface allows direct detection and feedback of machine position, avoiding the need for external devices. These and other functions will reduce wiring and allow smaller drives to be used, according to Mitsubishi.

The 15kg drives can deliver up to 200A (peak) for spindle motor applications, and 80A (peak) for three servodrive axes. Rated currents are 63A for spindle applications, and 15.8A for servo applications. Rated input voltages are 200–230A AC.

The new CNC drive will be unveiled at the Japan International Machine Tool Fair in Tokyo from 1–6 November, and will go on sale in December.