HepcoMotion claims a novel connector that it has introduced for its MCS aluminium frame and machine construction system, can cut the time needed to build a typical frame by up to four hours.

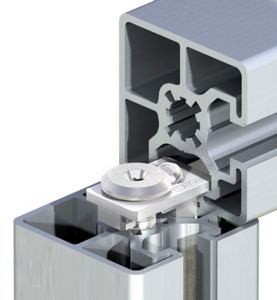

The RapiLok connector (shown above) is designed to secure two profile sections mounted at right angles to each other. The previous fixing method required cross-drilling of these profiles, but with the new connector, no machining is needed. Only one profile needs to be tapped and there are no other components involved, cutting costs as well as reducing inventory. The result is said to be neater joints that are rigid and reliable.

The only tool needed is a hexagon Allen key. The RapiLok locates against rotation and is therefore suitable for twisting loads. Serrated faces on the underside of the nut grip onto the smooth faces on the profile, making it suitable for applications where additional loads are applied.

The low-cost connector can be adjusted to allow profiles to be levelled during assembly. It can be used in multiple orientations and leaves the profile T-slots available to accommodate other system components, such as panels.