![]() Festo has developed a robotic hand designed to assist in assembly tasks on production lines, as well as having potential applications in service robotics and medical systems. The ExoHand made its debut at the recent Hannover Fair, where it was a runner-up in the prestigious Hermes innovation award.

Festo has developed a robotic hand designed to assist in assembly tasks on production lines, as well as having potential applications in service robotics and medical systems. The ExoHand made its debut at the recent Hannover Fair, where it was a runner-up in the prestigious Hermes innovation award.

Festo developed the device to meet the challenge of helping an ageing population to perform assembly tasks on production lines. It can also be used to control remote manipulation systems.

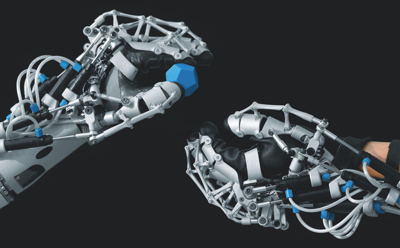

The device takes the form of a supportive exoskeleton that fits over a human hand. As well as moving the wearer’s fingers and amplifying their strength, information about their hand movements is also transmitted to the robotic hand in real time.

Eight pneumatic actuators move the exoskeleton, and sensors record various forces, angles and distances. Servopneumatic open- and closed loop control algorithms provide precise movement of the individual finger joints. The ExoHand thus supports various gripping and touching actions.

The pneumatic components control the individual finger joints. High forces can be transmitted precisely in a small space and with a low weight, without becoming restrictive or risking injury.

Despite the widespread use of automation, there are still many industrial assembly tasks that can be performed only by humans. Many are repetitive tasks that cause fatigue and can be particularly challenging for older workers. The ExoHand could help them to work longer without risking physical damage. It can also provide enhanced strength for assembly tasks.

Another role for the ExoHand is to manipulate a robotic hand remotely in industrial environments, allowing complex activities to be performed from a distance in dangerous or hazardous environments. The ExoHand can be worn over a human hand or an artificial hand made of silicone and can act as a robotic hand, as well as an interface between an operator and control system.

The hand can transmit feedback forces to the wearer, allowing them to feel shapes. This offers potential not only for remote manipulation, but also for navigation in virtual worlds.

Festo believes that the ExoHand could also have applications in service robotics and in medical rehabilitation. For example, it could help to treat the first signs of paralysis in stroke patients. If used with a brain-computer interface, the ExoHand could to create a closed feedback loop, help patients showing the first signs of paralysis to restore the missing connection between brain and hand.

An EEG from the brain could indicate a patient`s desire to open or close the hand. The active ExoHand would then perform the movement. The could result in a training effect, which over time would help patients to move their hands again without any technical assistance. Festo is working with the Centre for Integrative Neuroscience at the University Hospital Tübingen to develop this concept.