First `intelligent` conveyor will speed pick-and-place operations

![]() The German energy chain specialist igus is developing a novel conveyor system with integrated power and data supplies, that can be used to give each conveyor link a separate function – such as carrying sensors, grippers, cameras, tools or machining elements.

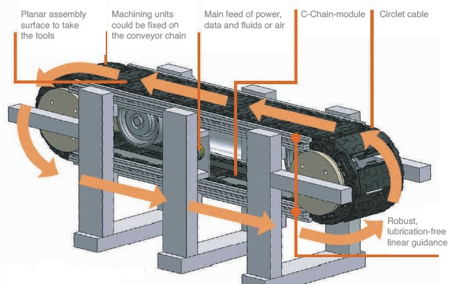

The German energy chain specialist igus is developing a novel conveyor system with integrated power and data supplies, that can be used to give each conveyor link a separate function – such as carrying sensors, grippers, cameras, tools or machining elements.

Igus describes the PickChain system (above) as “the first intelligent conveyor chain for pick-and-place systems”. A prototype version of the system was demonstrated at the recent Motek handling show in Germany and igus is looking for companies to act as beta testers for the system.

Preliminary specifications suggest that the PickChain will offer travel lengths of up to 8m (and possibly up to 30m) and will be able to operate at continuous speeds of 2–3m/s. Each 250mm-wide link in the conveyor chain – based on igus’ continuously circulating C-Chain system – can carry a load of around 5kg. Services such as power, data, air or other fluids can be fed to the links.

Igus predicts that the PickChain system will reduce pick-and-place times dramatically. As well as operating horizontally, it could also be used vertically or on its side.

A video showing the prototype system in action can be seen on igus’ Web site.