Hose coupling `eliminates whip risks`

The fluid connector specialist Stäubli claims to have eliminated the risk of compressed air hose whip with a new connector design that, it says, will improve safety and reliability as well as making hoses easier to handle.

Disconnecting pressurised air-lines can be hazardous if the downstream flexible hose still contains air under pressure, causing it to whip around violently. Hose whip speeds of up to 145km/h have been measured and the plug attached to the hose can become a dangerous projectile, capable of seriously injuring anyone nearby.

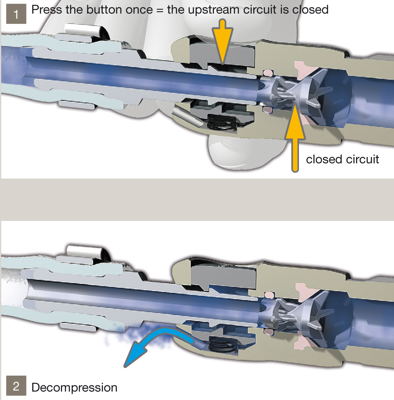

To disconnect Stäubli’s new RSI coupling, you press a button (as shown below) which triggers a controlled sequence of actions inside the coupling that allow disconnection in complete safety. First, the upstream compressed air circuit is closed. This is followed by decompression of the downstream circuit, and finally automatic disconnection of the plug, as soon as the pressure is low enough. Because the plug is no longer connected, airflow is impossible and safety is said to be guaranteed. The connectors comply with ISO 4414 for disconnection backlash prevention.

Because connectors often need to be fitted in awkward locations, the RSI system allows the disconnection button to be orientated into the most accessible position. For applications where gloves are worn, there is a raised-button version.

The leak-free RSI connector is available with nominal bores of 5.5, 8 or 11mm, each with a maximum pressure rating of 16 bar. The coupling body is made from a stainless and chromium steel mixture that offers corrosion protection and hardness. The couplings have a five-year warranty, provided that the plug and socket are made by Stäubli.