Bearing extends equipment lives in washdown applications

Baldor Electric has launched a mounted ball bearing with sealing and lubrication innovations that, it claims, can extend equipment lifetimes substantially in harsh, washdown environments, such as food and beverage plants. The Dodge Ultra Kleen bearings have stainless steel inserts and a patented sealing system and ball retainer that prevent washout in wet operating environments. They are claimed to have longer lives, and to need less relubrication, than standard designs.

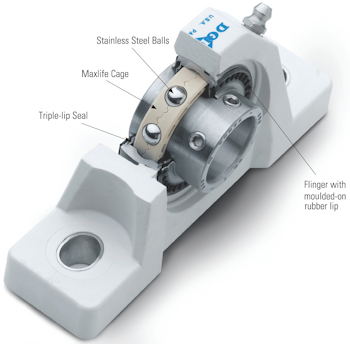

The new sealing system, called QuadGuard, consists of a triple-lip seal and a rubberised flinger. The seal`s three contact points keep the lubricant in and contaminants out, with minimal drag.

The moulded rubber flinger provides an extra barrier to contaminants. An external baffle enhances the removal of liquid as it rotates, while internal grease chambers prevent lubricant from being lost.

A new two-piece ball-retaining cage called Maxlife creates a grease compartment around each rolling element. The compartments provide constant contact between ball and grease so there is always an oil film to prevent wear and to minimise friction and heat. The construction also prevents the grease from being washed out.

The bearings are available in a variety of stainless steel and polymer housings, in imperial and metric sizes from 20-50mm.