Metering valves cut lubricant consumption by 25%

Schaeffler claims to have reduced, by more than 25%, the amount of lubricant consumed by linear recirculating roller bearings and guideway assemblies. It has developed special lubricant metering valves that provide precise doses of lubricant to the linear guides, reducing maintenance and servicing costs.

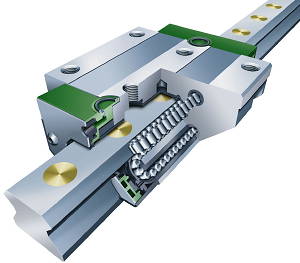

With conventional roller monorail guidance systems, the relubrication duct between the lubrication hole on the linear guide and the rolling elements can become empty, requiring more lubricant during relubrication to ensure reliable operation.

With centralised lubrication systems, a specific dose is provided per impulse, which can result in the lubricant arriving late in the rolling elements or, at worst, lubricant starvation. In extreme cases, the rolling elements and raceway can be damaged, leading to the complete failure of the linear system.

In Schaeffler’s new system (called SMDS), metering valves replace the standard O-ring seals. A paper seal between the end-plate and the lubrication duct prevents leakage of the lubricant from the ends, resulting in the 25% reduction in lubricant consumption compared to standard designs.

The valves prevent the lubricant duct from running dry, as well as avoiding inadequate lubrication or over-metering. They also allow precise relubrication using small quantities of lubricant. There is one valve for each side of the linear guide and one lubrication hole per carriage. The lubrication system is not affected by the mounting position.