2mm discs produce small, tough, accurate encoders

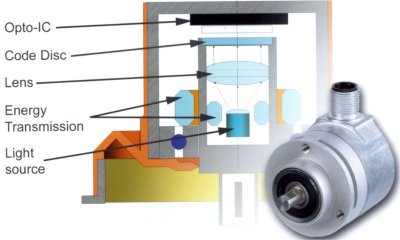

Sick|Stegmann has invested €1.9m and spent three years developing a new type of encoder disc with a code track radius of just 2mm. Called the MiniDisc (or MiDi), the rugged technology is claimed to result in several advantages, including a reduction in errors, and the ability to produce tiny encoders.

Sick|Stegmann has invested €1.9m and spent three years developing a new type of encoder disc with a code track radius of just 2mm. Called the MiniDisc (or MiDi), the rugged technology is claimed to result in several advantages, including a reduction in errors, and the ability to produce tiny encoders.

Because the whole disc is scanned constantly, the encoder circuitry can compensate for any eccentricity errors in ball bearings or shafts. The smaller radius is also said to remove many of the issues related to high angular speeds and means that the size of an encoder is now determined mainly by its mechanical and electrical connections.

Unlike conventional encoders, where a small area at the centre of the disc is glued to the encoder shaft, the MiDi disc is fitted inside the shaft and held securely around its edge. This, combined with its small size, makes it almost impossible to break or shake loose, thus rendering it impervious to shock or vibration.

Sick’s first encoder to exploit the new disc is the SKS/SKM36 which is designed for use as a master encoder for servo drives equipped with the Hiperface interface. The encoder, part of Sick’s SinCos range, is available in single-turn version (SKS), capable of resolving 4,096 steps/rev, or a multi-turn version (SKM), capable of measuring 4,096 steps/rev over 4,096 revolutions. The encoders are equipped with electronic "labels" allowing a drive to recognise their resolution automatically.