Novel bearings use tubes and truncated balls

At last month’s Hannover Fair, the Schaeffler Group was demonstrating two novel bearing designs: one using ball rolling elements with 15% of their non-load-carrying parts shaved off on both sides; and another using tube rollers. It was also showing a high-speed linear rail guide, capable of speeds of 10m/s, claimed to be the world’s fastest.

At last month’s Hannover Fair, the Schaeffler Group was demonstrating two novel bearing designs: one using ball rolling elements with 15% of their non-load-carrying parts shaved off on both sides; and another using tube rollers. It was also showing a high-speed linear rail guide, capable of speeds of 10m/s, claimed to be the world’s fastest.

The "ball roller" bearings, previewed last year, are claimed to be 20% narrower and to have a 20% higher radial load capacity than conventional ball bearings. They are being produced in single- and four-row formats with a typical single-row version incorporating 11 of the new rolling elements instead of the conventional nine, and being 13.5mm wide, instead of the usual 17mm. The bearings (shown above) are lighter and exhibit less friction than traditional designs.

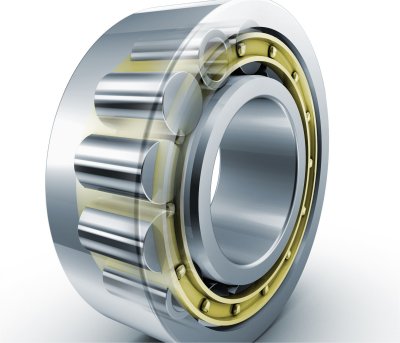

The tube roller bearing (above) is being touted as an alternative to cylindrical roller bearings for applications where low radial loading can lead to slippage and possible damage. Three of the standard cylindrical rollers are replaced by tubes with a slightly larger diameter, producing a slight preload in the bearing. Under low-load conditions, the tube rollers drive the roller set; at higher loads, they retract and the forces are spread onto the other rolling elements.

Compared to standard axially-preloaded cylindrical roller bearings (with which they are interchangeable), the new bearings are said to be easier to design and install. Schaeffler engineers are currently performing endurance tests on the new design before applying them in selected customer projects.

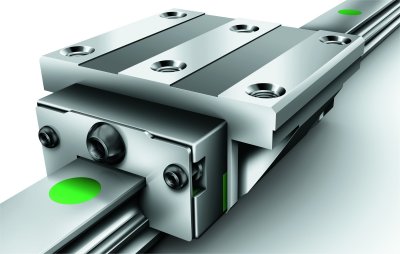

Schaeffler claims that its 10m/s linear rail guide (shown above) will have a service life 30% longer than those of its rivals. The KUVE-B-HS, based on a four-row linear recirculating ball bearing assembly, is designed to minimise positioning, travel and throughput times, and to maximise dynamics.