Graphical drives programming set for a Hannover debut

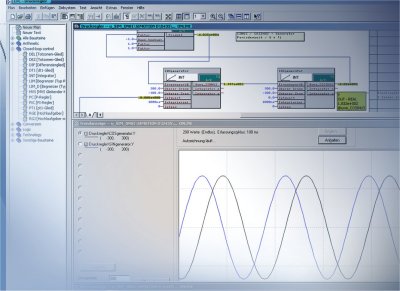

At next monthís Hannover Fair, Siemens will unveil a graphical programming system for its variable speed drives and motion controls, called Drive Control Chart (DCC). The system uses drag-and-drop techniques to link function blocks from a large library of control, mathematical and logic functions.

The DCC editor will allow open- and closed-loop control functions to be configured easily, using graphical parameterisation. The system, intended for use with Siemensí Simotion motion controls as well as its Sinamics S120 drives, includes diagnostic functions to verify programs and to identify the causes of faults.

The function blocks include items such as PI controllers, ramp generators and coilers, as well as a wide range of mathematical and logic functions.

When used with S120 drives, DDC will allow drive-related tasks to be performed inside the converter, taking the load off higher-level controls. In addition, Siemens claims that this local processing will improve machine performance.

Siemens will also be launching a new version of its Simotion control system at Hannover, providing extra Profinet functions for modular machines. The system can now be used to synchronise electrical and hydraulic drives.

The new version (4.1) will also allow Simotion controllers to be configured simultaneously as controllers and devices at the same Profinet interface, making it easy to implement hierarchical automation structures and modular machine architectures, without needing extra components.

Simotion 4.1 will also offer a function that can interpolate up to three axes of motion, and synchronise a fourth axis with the movements. The function, which supports linear, circular and polynomial interpolation, can be programmed using either the Structured Text or Motion Control Chart languages.