The edge devices can support conventional automation components, such as controllers, to process greater amounts of data and to deliver information to improve productivity. They can also help to implement applications such as condition monitoring and predictive maintenance.

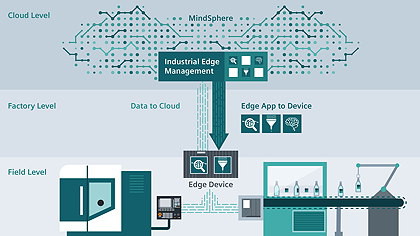

Siemens’ Industrial Edge includes a management system that provides central control of all connected edge devices. Users can use it to install software (Edge Apps) from an Edge App Store located in a backend system, such as MindSphere.

Siemens is releasing a series of edge applications including data processing, data visualisation via Web servers, and data transfer to the cloud. These apps – or those from third parties or even end-users – can be used in combination with cloud connections to form an integrated hardware and software ecosystem.

Siemens Industrial Edge platform expands automation devices to include cloud functions such as data analysis, or software and device management

Initially, Siemens Industrial Edge is supporting MindSphere cloud transfer protocols. In future it will also support MQTT (Message Queuing Telemetry Transport), ensuring that data transfers are safe and secure.