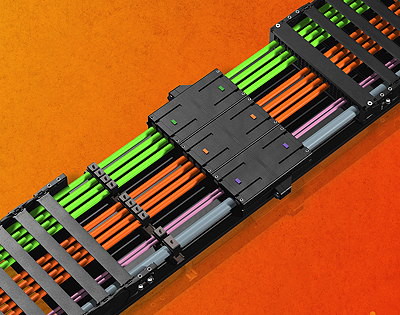

These modules can be mounted on an e-chain, between different e-chains, or directly onto switch cabinets.

Each housing can contain up to four different plug inserts. The housings are joined together, allowing almost unlimited permutations. Accessories such as mounting plates, label carriers, locking elements and strain reliefs are used to create complete plug-in modules.

“Due to the flat housing design, module connect saves space and enables a high contact density for any application,” says igus UK director, Justin Leonard. Each module can be adapted to the filling and geometry of an energy chain in one or more layers.

igus’ module connect system offers a flexible way of making many connections in a limited space

“Customers will save time on harnessing as well as assembly, especially for long travels and heavily loaded multi-axis systems,” he adds. “Above all, this offers the customer cost savings in production.”

The module connect system is part of igus’ readychain family of energy chains.