Conventional robot technologies and their controls are designed to handle objects where conditions change in a predictable and predetermined way.

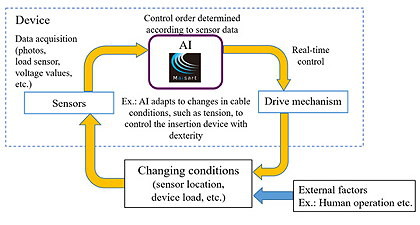

The new technology uses multiple types of sensor and real-time controls to handle flexible items that may alter their shapes, or where conditions may be changing. It recognises the changes by applying Mitsubishi’s Maisart smart-learning AI and makes repeated estimations based on deep-learning techniques. Tests have shown that the technology can reduce learning times and can adapt to changes in conditions in just 3.5ms.

The technology can redesign and optimise control algorithms automatically in real time. Mitsubishi says that this will free designers from having to reformulate complex control algorithms.

Mitsubishi's AI technology allows robots to adapt and optimise their movements in real time to suit changing operating conditions

Applying the new technology to machines such as industrial robots will allow them to adapt to objects that are conventionally difficult to handle. Japanese industry is particularly interested in adaptable industrial robots which could help to overcome the country’s falling numbers of working-age personnel.

The new technology is protected by six global and six Japanese patents.