The modules are designed to be inserted directly into application-specific distribution boards that carry signals and power. Pre-configured cable harnesses replace costly individual wiring and minimise the risk of faulty wiring.

Initially, Beckhoff is offering three plug-in modules:

• The EJ7047 5A stepper motor module with two inputs for limit switches – the second input can be configured as an output for a holding brake, for example. Users can optionally implement vector control for enhanced dynamics and reduced power consumption.

• The EJ7211-0010 servomotor module which uses Beckhoff’s One Cable Technology, combining power and absolute feedback in a single cable. The module delivers currents of up to 4.5A. It can read the identification plate of an AM81xx motor electronically, simplifying wiring and commissioning. The control technology, based on a field-oriented current and PI speed control system, is suitable for dynamic positioning tasks.

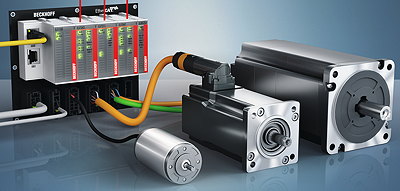

Beckhoff’s drive modules plug into a distribution board that carries signals and power

• The EJ7342 two-channel DC motor output stage, which can operate two DC motors up to 3.5A, and offers galvanic isolation. Speed and position are set from an automation device using a 16-bit value, allowing simple servo axes to be implemented by connecting incremental encoders.

A brake chopper module is available for dynamic applications and when feeding multiple axes from one power supply. It protects the system against overvoltage damage by absorbing part of the energy. If the voltage exceeds its capacity, the excess energy is discharged via an external resistor.