The results are fed into a microcontroller. If a particular signal changes, the controller can identify the underlying fault or error and respond accordingly. The “sentient” motors can be networked to form an integrated complex that could open up opportunities in terms of maintenance, quality assurance and production. It could also lead to systems where if one motor fails, another takes over automatically.

To gather data from a motor, Nienhaus and his team monitor the distribution of the magnetic field strength within the motor and how it changes as the rotor spins. They use this data can be used to compute the position of the rotor and to draw other inferences about the status of the motor, allowing it to be controlled efficiently and error states to be detected reliably.

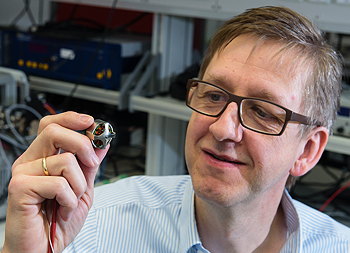

Professor Matthias Nienhaus from the University of Saarland is developing a new kind of self-monitoring motor that doesn’t need sensors. Photo: Oliver Dietze / Saarland University

Nienhaus is currently testing several different methodologies to determine those best suited to acquiring data from motors.

The aim is to develop a suite of hardware and software modules that will make it easier to monitor and control drives and positioning systems, paving the way to fast, precise manufacturing processes that can be monitored and adjusted in real time. The researchers hope to identify which motor speeds generate the best data and which type of motor is best suited for this type of application.

Results from the project will be on show on the Saarland Research and Innovation stand at the Hannover Fair in April.